Application of GC-MS in Food Safety Testing

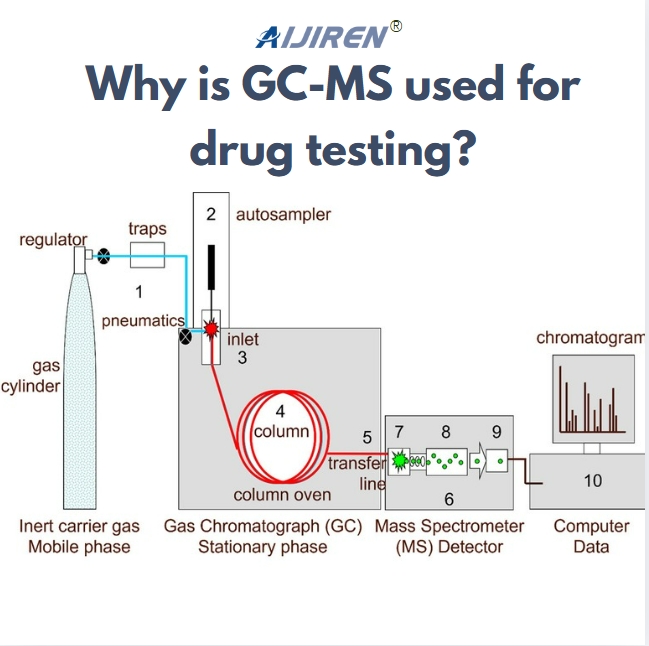

GC-MS is essential for identifying and quantifying contaminants and residues in food. Its high sensitivity and selectivity make it particularly suitable for analyzing low-polarity, volatile, and thermally stable compounds, which are common in food safety issues. The technique is essential for detecting harmful substances such as pesticides, heavy metals, and other contaminants that may pose a risk to consumer health.

In order to effectively improve the accuracy of GC-MS detection of food ingredients, analysis is carried out according to the actual application situation.

First, fully understand the characteristics of the food samples to be tested, and scientifically and rationally select the GC-MS method. At the same time, formulate a complete detection experiment and operation process, and carry out the detection preparation work with the specific application method of gas chromatography. Effectively control and reduce various unstable factors in the experimental stage to prevent the impact on food detection results and ensure that the accuracy of GC-MS application to food detection is improved.

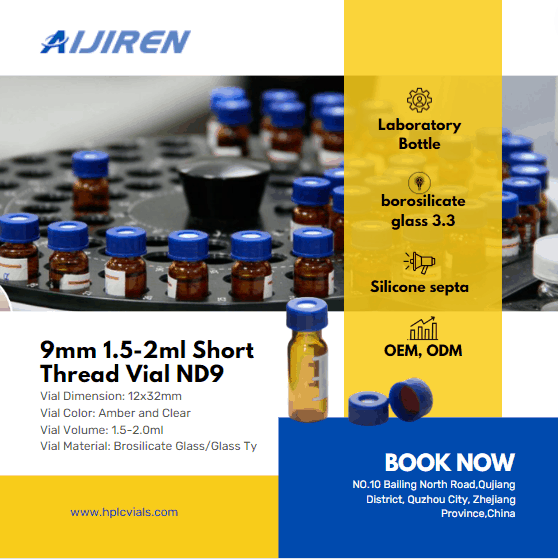

Second, carefully set the parameters of the gas chromatography-mass spectrometry equipment. For example: the temperature setting of the column box, the selection of the detector, the selection of the chromatographic column, etc. must meet the instrument requirements of the test. Optimize the overall environment of food inspection to ensure the practicality and scientificity of the instrument selection. Before the testing staff officially uses the GC-MS instrument, they should check the accuracy of the equipment again. Compare the test experiments and analyze them to ensure that food testing meets the requirements of gas chromatography-mass spectrometry technology.