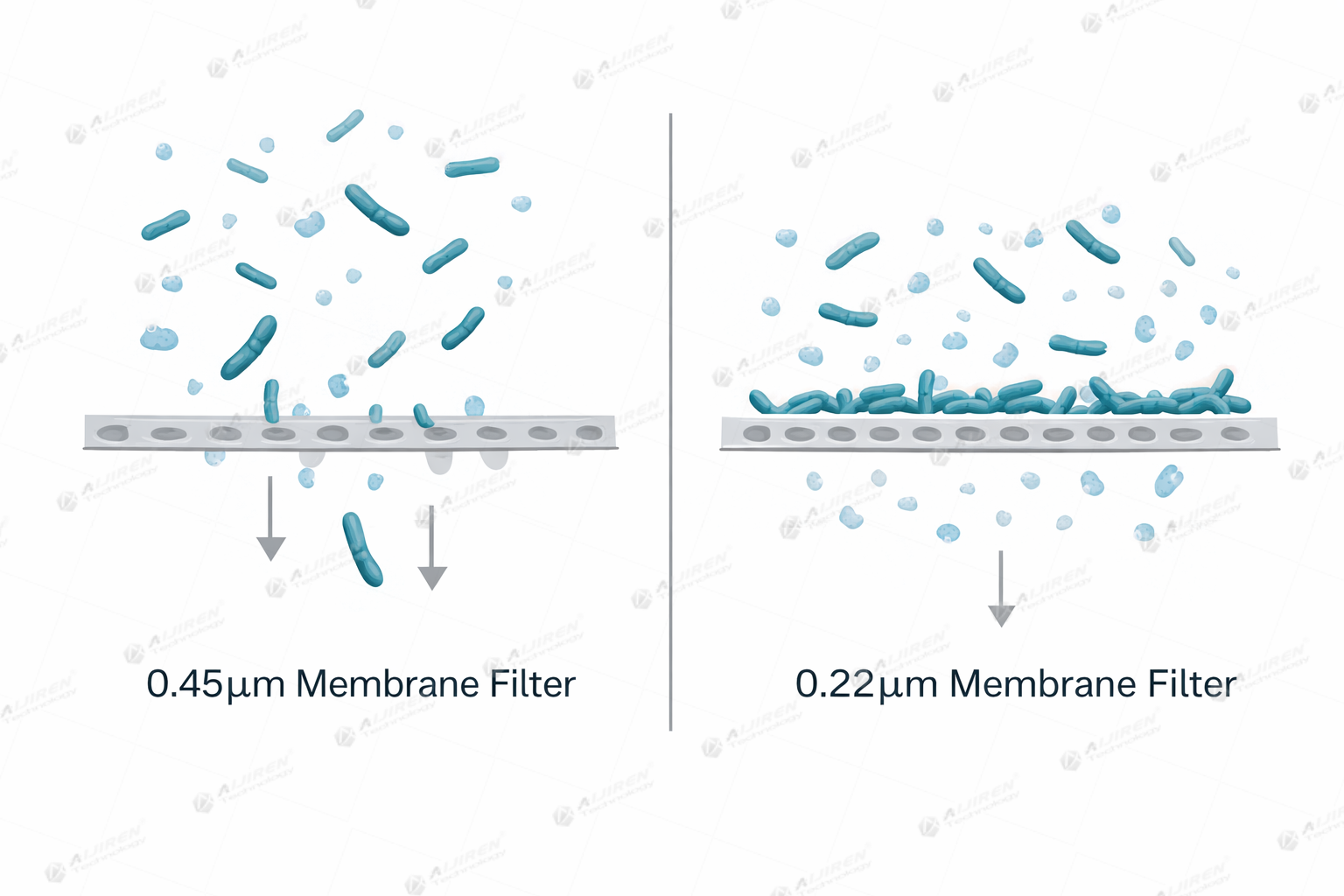

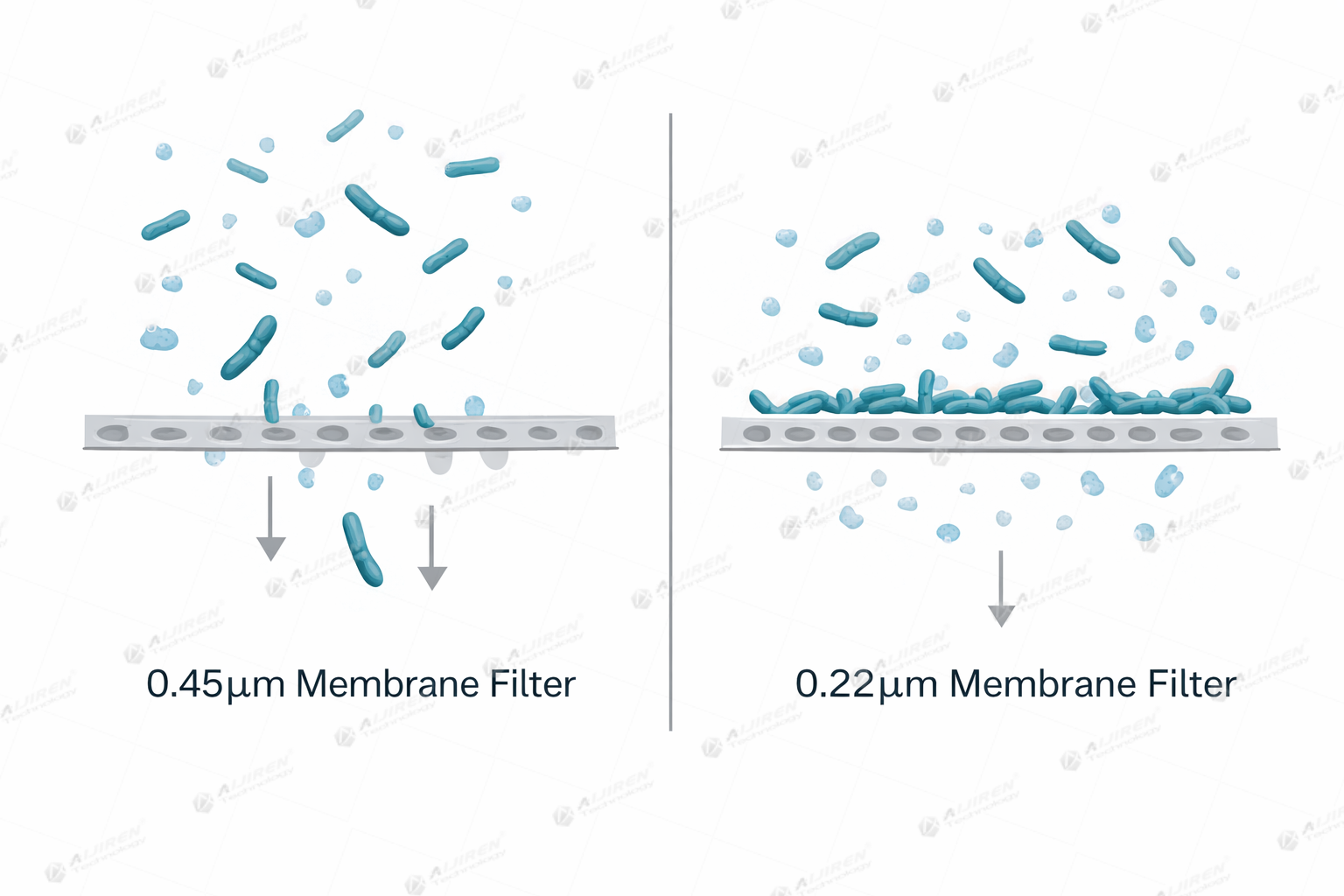

Why is the 0.22 micron (µm) filter considered the "Gold Standard" in laboratories worldwide? While a 0.45 µm filter handles general clarification, the 0.22 µm membrane is the legal and scientific threshold for true sterilization. It is the only pore size validated to remove Brevundimonas diminuta, the industry-standard "challenge organism" for sterile liquid processing.

However, selecting a filter is more than just picking a pore size. If you choose the wrong membrane chemistry or diameter, you risk losing your precious analyte or damaging your $200k HPLC system. This guide provides the deep technical insight needed to make the right choice every time.

1. Quick Decision Matrix: Matching Membrane to Application

Before diving into the physics, use this high-level table to narrow down your choices based on your specific sample type.

| Sample Category |

Recommended 0.22 µm Membrane |

Why It Works |

| Protein-rich (Serum/Media) |

PES (Polyethersulfone) |

Lowest binding; preserves your proteins. |

| Aggressive Organics (THF/ACN) |

Hydrophobic PTFE |

Won't dissolve; zero extractables. |

| Trace Analysis (LC-MS) |

Certified PTFE / RC |

Minimal background noise (Ghost Peaks). |

| General HPLC Aqueous Prep |

Nylon / PVDF |

Excellent wetting; high dirt capacity. |

| Air & Gas Venting |

Hydrophobic PTFE |

Blocks moisture while allowing gas flow. |

2. Deep Dive: The Chemistry of 0.22 µm Membranes

Not all "plastic" filters are the same. The molecular structure of the membrane dictates whether your experiment succeeds or fails.

PES (Polyethersulfone) – The Speed King

PES is the go-to for biological labs. Its asymmetric pore structure acts like a funnel, allowing for exceptionally high flow rates.

PTFE (Polytetrafluoroethylene) – The Chemical Tank

PTFE is virtually inert. Whether you are filtering concentrated acids or aggressive HPLC solvents like Acetonitrile, PTFE won't leach "junk" into your sample.

Selecting the correct membrane material is as crucial as the pore size itself. For complex HPLC analysis involving both aqueous and organic solvents, our

0.22um hydrophilic PTFE syringe filters

offer superior chemical resistance and high recovery rates. Conversely, for biological samples or protein filtration,

sterile PES syringe filter options

provide the low protein binding properties necessary to maintain sample integrity.

Nylon and PVDF – The Robust Workhorses

Nylon is naturally hydrophilic (no pre-wetting needed) and has high mechanical strength. However, be careful: Nylon can bind to certain proteins and polar compounds. PVDF is a great middle-ground, offering better chemical resistance than Nylon but higher protein recovery.

3. Physical Parameters: Choosing Diameter and Capacity

A 0.22 µm filter is only as good as its housing. Choosing the wrong size leads to two major problems: Sample Loss or Membrane Rupture.

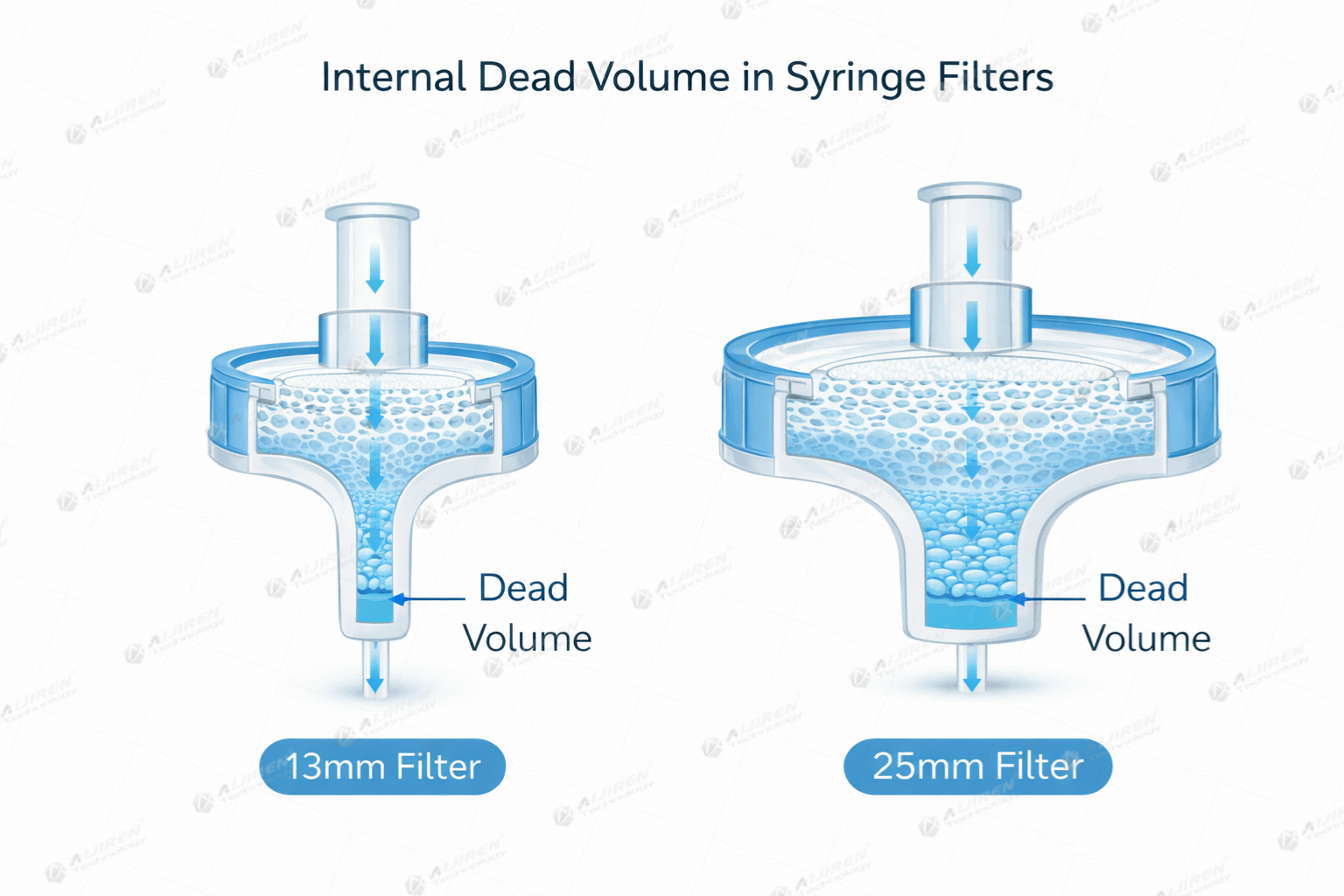

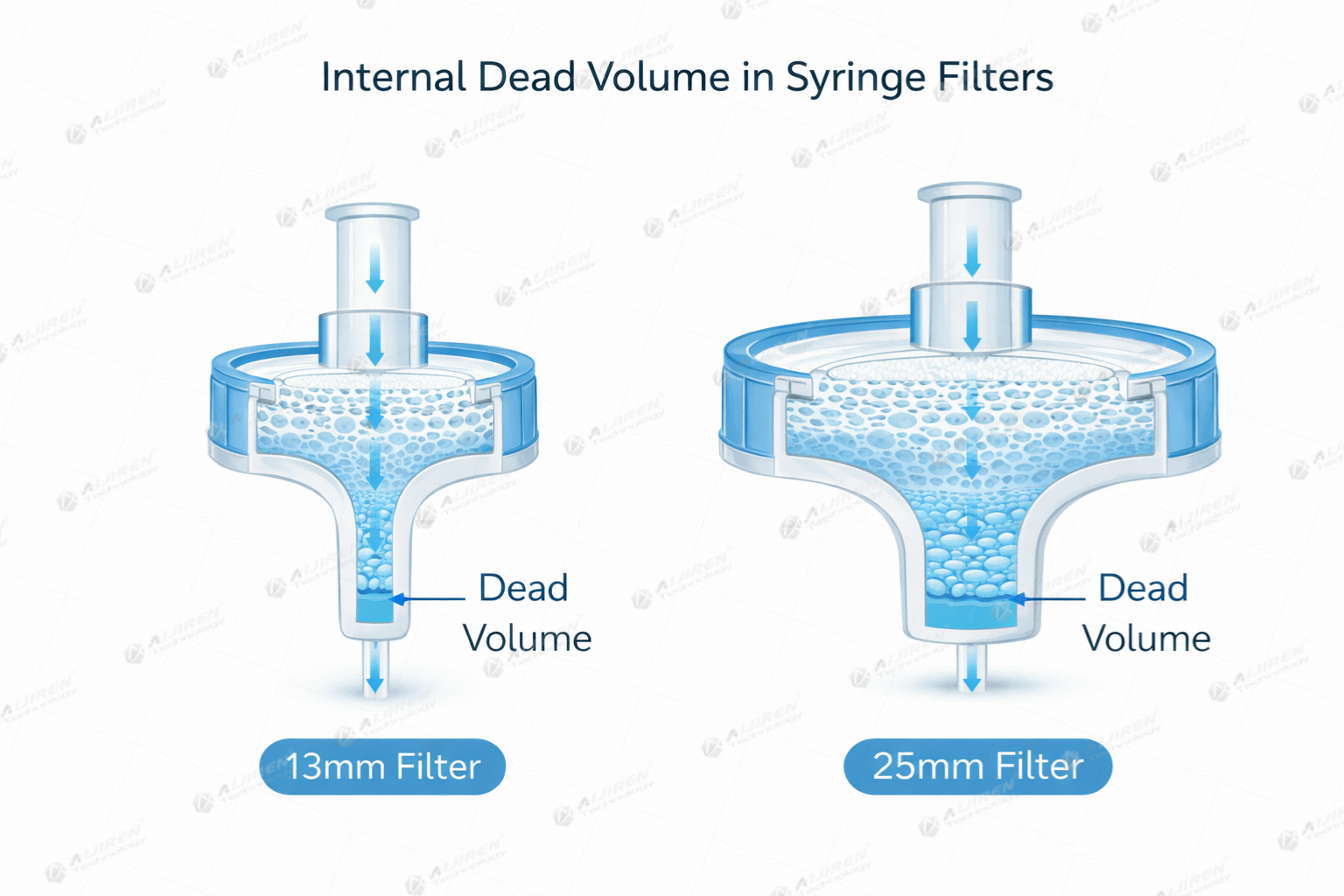

13mm vs. 25mm/30mm – The "Hold-up Volume" Problem

-

13mm Diameter: Use this for samples < 10 mL. A 13mm filter has a "hold-up volume" of less than 50 µL. Using a 25mm filter for a 1 mL sample is a mistake—you will lose a significant portion of your sample inside the filter.

-

25mm/30mm Diameter: Use this for 10-100 mL. The larger surface area ($3.9 cm²) reduces the pressure required to push the liquid through, preventing operator fatigue and housing failure.

-

Efficient filtration is only the first step; how you store the filtered sample matters equally. To prevent secondary contamination or evaporation, filtered samples should be immediately transferred into a high-quality container. Whether your system requires

9mm screw top vials

or the more secure

11mm snap vials

, ensuring

autosampler compatibility

is key to preventing needle damage and ensuring precise injections.

Luer Lock vs. Luer Slip

For 0.22 µm filters, always choose Luer Lock. Because the pores are so small, the backpressure is high. A Luer Slip tip can easily pop off under pressure, spraying your sample (and potentially hazardous chemicals) across the bench.

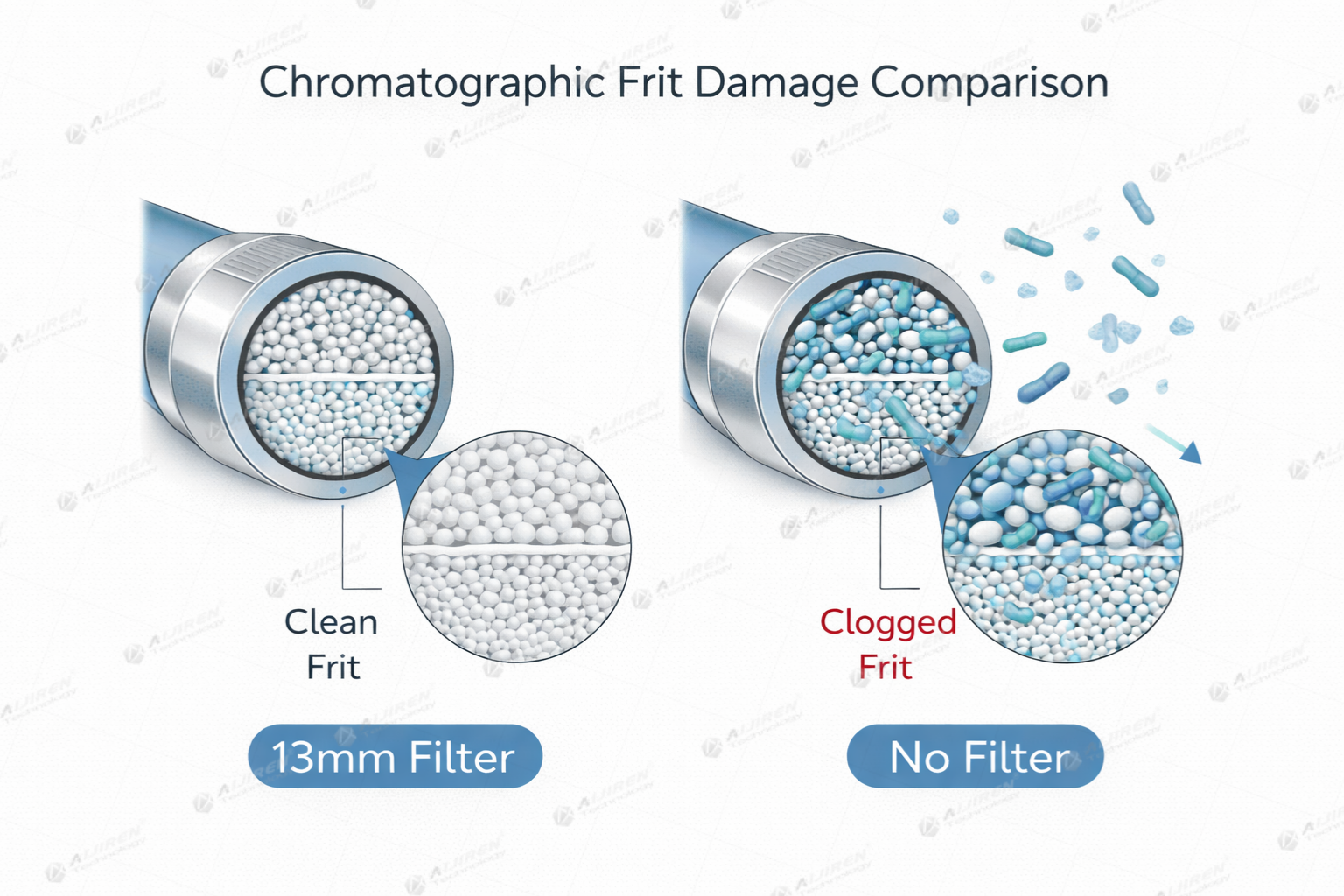

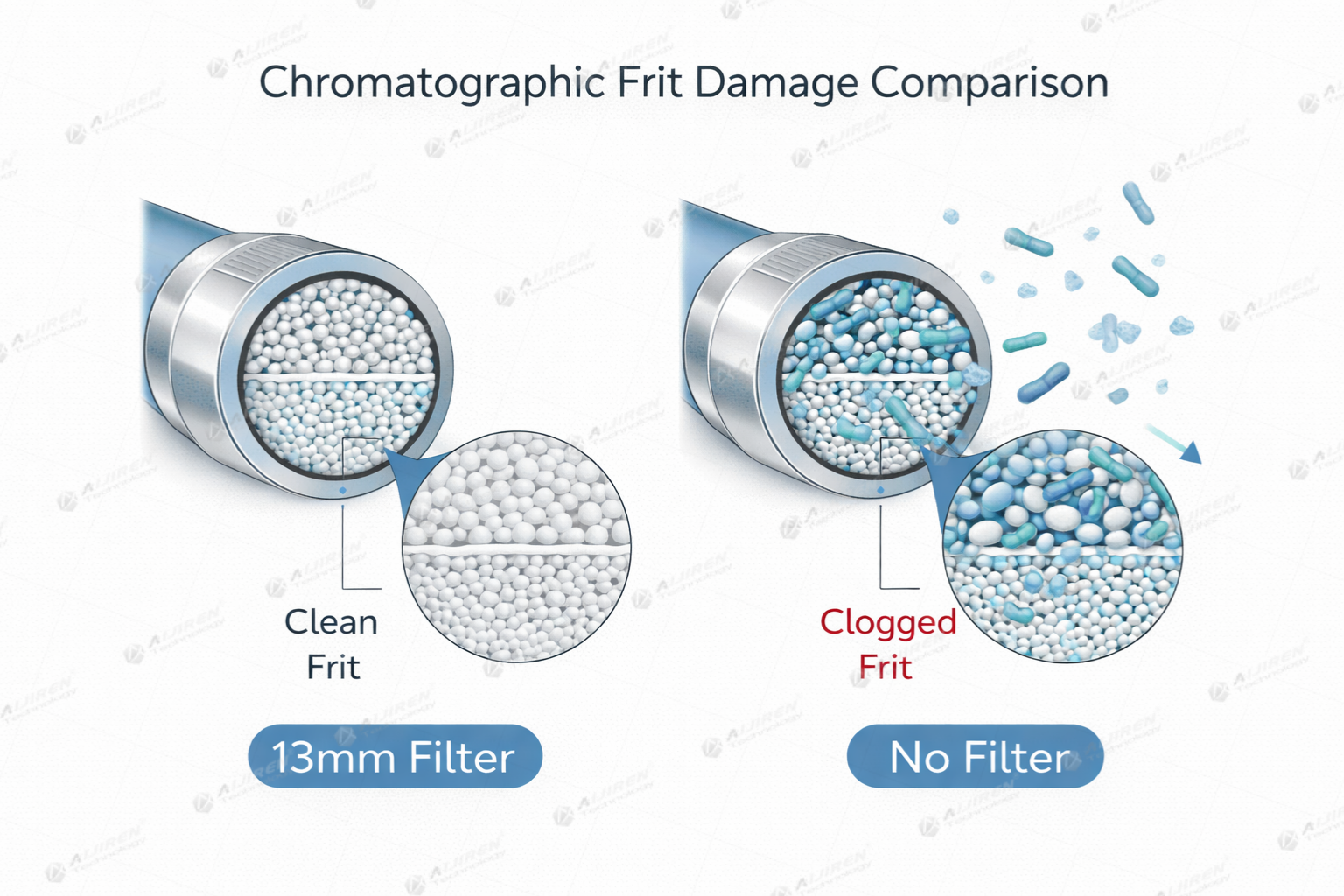

4. Why 0.22 µm is Mandatory for LC-MS and UHPLC

If you are using a modern UHPLC with sub-2-micron column particles, a 0.45 µm filter is a recipe for disaster.

Protecting the Frit

In UHPLC, the column frits are incredibly fine. Particles that pass through a 0.45 µm filter will eventually accumulate on the frit, leading to increased backpressure and shortened column life. Switching to 0.22 µm filtration can double the lifespan of an expensive column.

Eliminating Ion Suppression

In LC-MS, you aren't just worried about particles; you're worried about extractables. Cheap filters leach surfactants that "blind" the mass spec detector.

One of the most common challenges in trace analysis is baseline noise and ghost peaks, which are often caused by poor filtration. Using a certified 0.22µm filter significantly reduces particulate interference. For analysts struggling with consistent results, we recommend exploring our comprehensive guide on the

main reasons and solutions for HPLC sensitivity issues

, which highlights the synergy between clean samples and optimal column performance.

5. Quality Assurance: Integrity Testing and Sterility

How do you know that "0.22 µm" on the label is accurate? In regulated industries (GMP/GLP), validation is key.

The Bubble Point Test

The Bubble Point test is the industry standard for verifying pore size. It calculates the pressure needed to force air through a wet membrane. For a 0.22 µm membrane, the pressure required is significantly higher than for a 0.45 µm. High-quality manufacturers like Aijiren perform this test on every batch to ensure 100% integrity.

Gamma Irradiation and Packaging

If your application requires sterility, look for filters that are Gamma Sterilized and individually blister-packed. Avoid "bulk-packed" filters for sterile work, as the risk of cross-contamination during handling is too high.

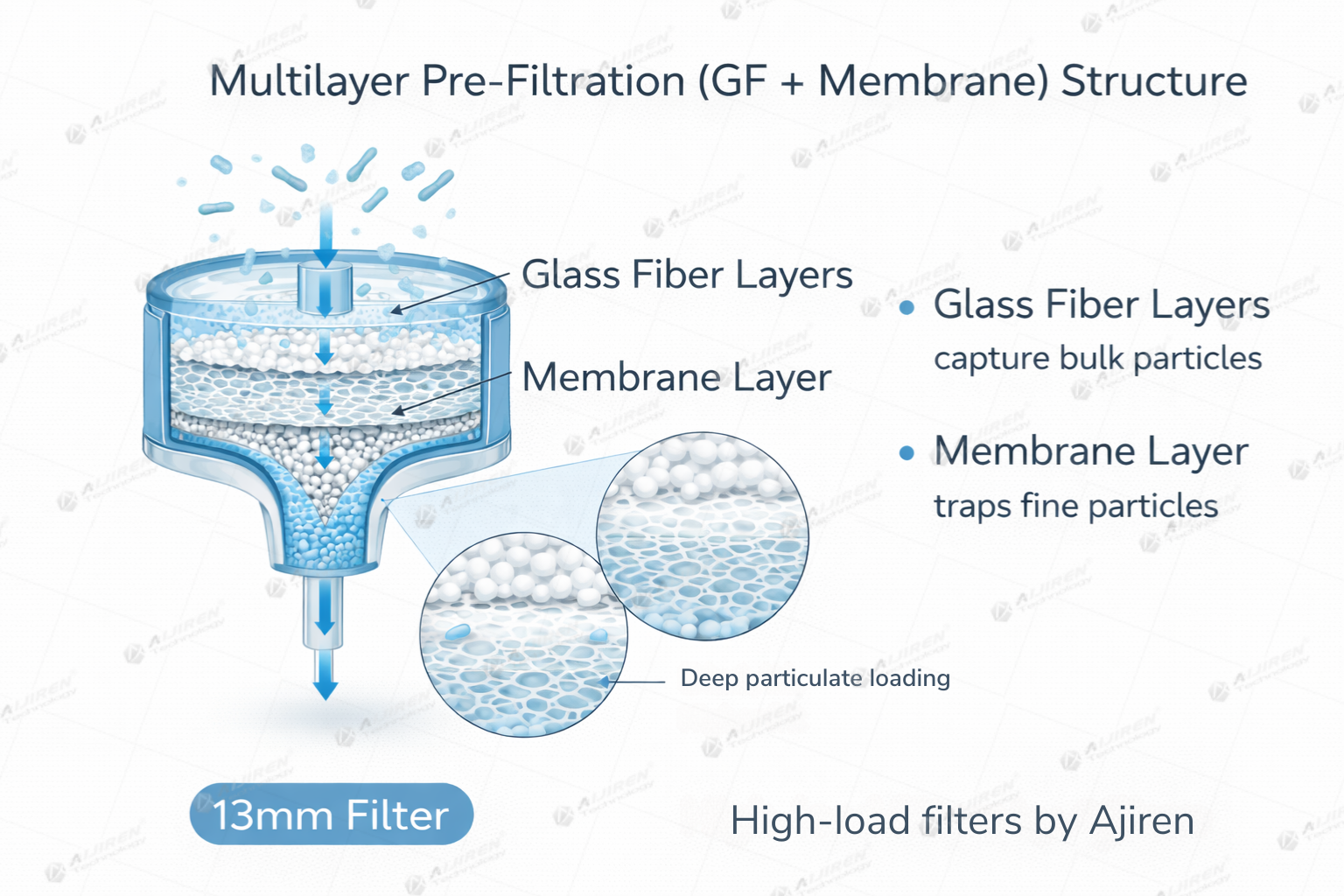

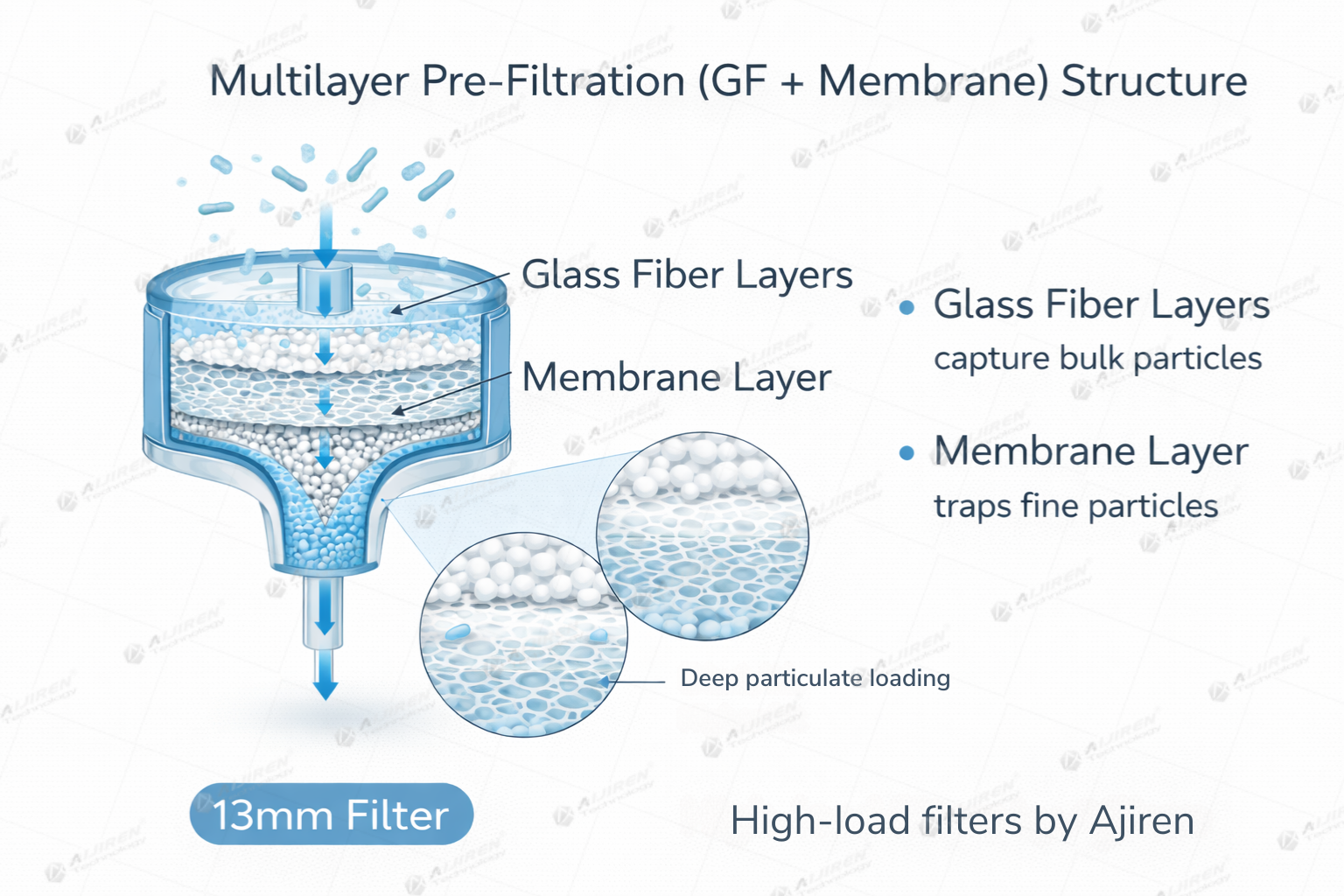

6. Troubleshooting: When Your 0.22 µm Filter Clogs

It is a common frustration: you try to filter a "dirty" sample, and the 0.22 µm filter stops working after 0.5 mL.

The Pre-filtration Strategy

Instead of struggling, use a Multi-layered Filter. These contain a Glass Fiber (GF) pre-filter sitting on top of the 0.22 µm membrane. The GF layer catches the large debris (lipids, proteins, particulates), allowing the 0.22 µm membrane to do its job of fine filtration without clogging.

Viscosity and Temperature

Cold samples are more viscous and harder to filter. If possible, let your sample reach room temperature before filtration to reduce the pressure required.

Professional Insights

Q: Does a 0.22 µm filter remove viruses?

A: No. While it effectively removes all bacteria, most viruses (0.02 µm to 0.3 µm) can pass through. For virus removal, you need an Ultrafiltration (UF) membrane or a 0.1 µm rated filter.

Q: Can I autoclave my syringe filters?

A: Only if the housing is made of Polypropylene (PP) and the membrane is compatible (like PTFE or PVDF). However, pre-sterilized Gamma-irradiated filters are always more reliable for sterile workflows.

Q: Is there a difference between 0.2 µm and 0.22 µm?

A: In the chromatography world, these terms are used interchangeably. Both refer to the same sterilization-grade filtration level.

Conclusion: The Cost of Choosing the Wrong Filter

Choosing a 0.22 micron filter is more than a line item in your lab budget—it is an insurance policy for your data and your instruments. By matching the right membrane chemistry with the correct physical parameters, you ensure reproducible results and protect your expensive HPLC columns.

While filters are indispensable disposables in the lab, many lab managers also look for ways to optimize overall costs without sacrificing quality. If you are interested in maintaining your glass consumables, check out our insights on whether

chromatography vials and closures can be reused

, along with our

5 efficient cleaning methods

to help maintain sample integrity.

Looking for high-performance 0.22 µm filters for your lab?

[Browse Aijiren’s Certified Syringe Filters] or contact our technical team for a free sample pack to test against your most challenging samples.

English

English

Chinese

Chinese